AIB Inspected: Making Sure Your Food is in Good Hands

When deciding on a 3PL company, many factors contribute to the decision you make. Depending on what kind of product you need shipped, certain factors may be more important than others. In the area of food, safety is a factor that should be at the top of your list. One of the simplest ways to find out if a potential 3PL partner is operating under best practices for food handling and distribution is to see if they have been inspected by the AIB, the American Institute of Baking.

The AIB provides inspections for food distribution centers throughout the world. Although these inspections aren’t mandatory in the United States, they are considered very important, and most potential partners would require a satisfactory score on their AIB inspections. So, the question is, what exactly goes on in an AIB inspection, and what does a high score on an AIB inspection mean for potential customers?

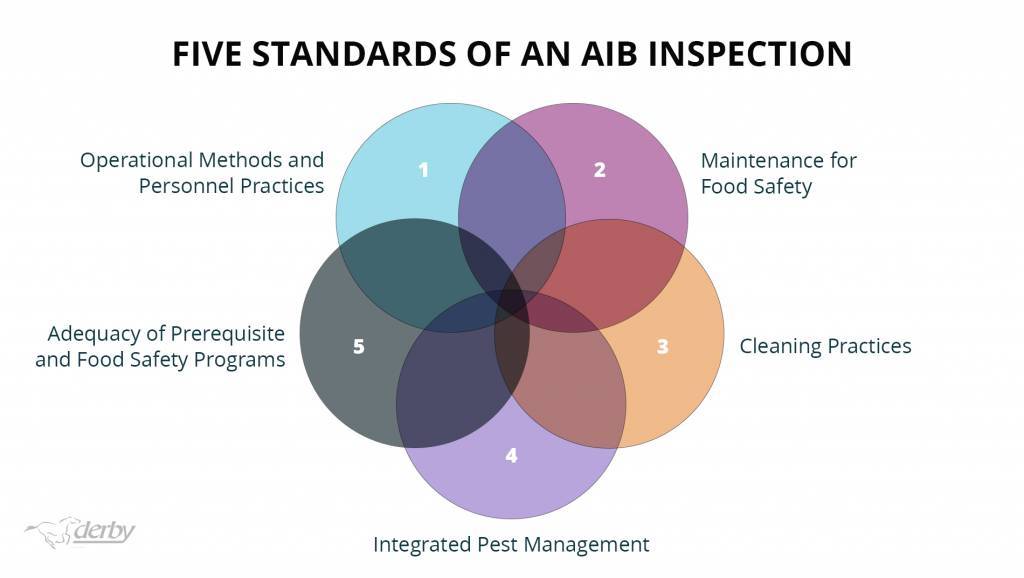

The Five Standards For An AIB Inspection

An AIB inspection consists of two elements. The first part of an inspection is a walk-through inspection conducted by AIB inspectors. This is a comprehensive review of the facility to assess how various elements function within the facility during realtime. The second phase is a thorough review of control systems in place, including a review of documentation for such concerns as Hazard Analysis and Critical Control Points (HACCP) and policies for product recall. According to the AIB, it can take some facilities up to a year to effectively prepare for a successful AIB inspection.

In the following list, we’ll take a look at the five standards of AIB inspection and highlight some of the more important criteria that are included in the review process.

1. Operational Methods and personnel Practices

The receipt, storage, monitoring, handling, and processing of raw materials to manufacture and distribute safe final product” – AIB

This first part of an AIB inspection reviews the methods and practices which are associated with how well a 3PL facility handles food product reception, preparation and shipment. There are 38 different criteria in the Methods and Personnel Practices portion of the inspection. Here are five of them:

Rejection of Shipments of Dry Goods & Perishables:

An assessment of the facility’s ability to safeguard against the entry of potentially contaminated raw materials and finished product. This includes the rejection of food products shipped in damaged, infested or dirty containers and vehicles.

Storage Practices and Conditions:

This part of the inspection seeks to ensure that raw foodstuffs and finished products are stored in such a manner that they meet the requirements for safe storage to protect them from contamination.

Raw Material/Finished Product Inventory:

This is to ensure that the inventory of raw materials for food production and the finished products are maintained at levels to ensure freshness and lack of infestation.

Bulk Material Handling:

This is a review of materials receiving practices to ensure that bulk systems, unloading areas and other high-traffic areas within the facility do not introduce external contaminants into the facility.

Temperature-Sensitive Materials:

This part of the inspection is conducted to ensure that food products which are susceptible to the growth of pathogenic organisms are properly stored at temperatures which prevent the development of contamination from pathogens.

2. Maintenance for Food Safety

“The design, upkeep, and management of equipment, buildings, and grounds to provide a sanitary, efficient, and reliable manufacturing environment” – AIB

Section Two of an AIB inspection concerns maintenance standards and deals with such issues as whether or not the facility’s drainage systems prevent mold or ammonia outbreaks, or that only food-grade lubricants are used on processing and packaging equipment. Here is a look a few of the key factors for the maintenance for food safety inspection:

Facility Location:

The physical location of a facility is closely reviewed to ensure that local activities of surrounding operations are not able to effect product contamination.

Floors and Drains:

This part of the inspection looks closely and flooring design and maintenance. It strives to make certain that flooring materials are easily cleaned and maintained and that they are sloped to direct water flow to effective draining.

Pest Prevention:

This section of the inspection strives to ascertain that the physical structure of the facility, its maintenance, and the materials in use support the Integrated Pest Management (IPM) Program.

Temperature Measuring Devices:

During this phase of the inspection, temperature measuring devices such as thermostats and other controls on equipment, such as pasteurization processing, are properly functioning and regularly calibrated.

Cross Contamination Prevention:

AIB Inspectors will review the production process to ensure that operations are segregated based upon needs, materials, processes, equipment types, and even that air filtration systems are properly in place to prevent contamination.

3. Cleaning Practices

“The cleaning and sanitizing of equipment, utensils, and buildings to provide a wholesome and safe processing environment” – AIB

Cleaning standards of an AIB inspection are similar to maintenance standards but are more focused on sanitation practices rather than prevention standards. These criteria essentially involve making certain that processing equipment is properly cleaned, maintained, and stored. This takes into account virtually everything for basic housekeeping to Clean In Place (CIP) systems for cleaning the interior surfaces of enclosed food processing equipment. The following are some of the criteria AIB inspectors review:

Cleaning:

In terms of an AIB inspection, cleaning means more than simply sweeping up and mopping the floor. The review ensures that cleaning is done in a fashion that prevents the contamination of raw foods, products and production equipment.

Food Contact Cleaning Compounds and Sanitizers:

This is an effort to ensure that all sanitizers and cleaning solvents are approved for contact with food and that they are properly labeled and securely stored in an area away from food production and storage areas.

Equipment and Tools:

If not properly cleaned and maintained, cleaning equipment itself can become a possible source of food contamination. This part of the inspection gives assurance that the cleaning equipment itself is properly cleaned.

Daily Cleaning (Housekeeping):

This is an examination of the daily cleaning practices which are designed to keep work and production areas clean and prevent food contamination.

Clean in Place Systems (CIPs) Systems:

CIPs are cleaning systems which are used to clean the interior surfaces of enclosed food processing systems. These systems allow for the cleaning of equipment and prevention of contamination without the necessity of disassembling the machinery.

4. Integrated Pest Management

“The assessment, monitoring, and management of pest activity to identify, prevent, and eliminate conditions that could promote or sustain a pest population” – AIB

Integrated pest management standards make sure that a facility has proper pest control practices in place to prevent the entry of rodents, insects, birds and other animals from entering the facility and contaminating food products, as well as ongoing contracts with a qualified pest control provider. The following are some of the criteria that AIB inspectors review:

Integrated Pest Management (IPM) Program:

An IPM is a written program which outlines and defines the pest control practices in place to keep pest issues under control. It should be written and implemented by either trained personnel, or a registered or licensed pest control service.

Facility Assessment:

Inspectors will conduct an annual review of all inside and outside areas of the facility to ensure the IPM program is in place and being conducted by properly trained personnel.

Signed Contracts, Credentials and Competencies:

In addition to making sure the 3PL facility has signed contracts with properly certified IPM providers, inspectors will also review the certifications of each individual who performs pest management services. This includes a current copy of the pest management company’s license and an active certificate of insurance from the facility.

Pesticide Control

AIB inspectors will review the facility’s Chemical Control Program to ensure that pesticides are properly stored in a secure location with limited access. The will also review documentation of pesticide labeling, safety and application.

Wildlife, Bird Control, Interior Rodent Monitoring Devices and Insect Light Traps

These criteria actually cover half a dozen requirements, but essentially provide for the inspection of interior and exterior rodent monitoring devices which help prevent entry of rodents and facilitate the capture of rodents which may get into the facility. Likewise, the AIB inspectors will look at controls in place for netting and traps to keep birds out of the facility as well as light traps for insects.

5. Adequacy of the Prerequisite & Food Safety Programs

“The coordination of management support, cross-functional teams, documentation, education, training, and monitoring systems to ensure all departments of the facility work together effectively to deliver a wholesome and safe final product.” – AIB

The final standard for an AIB inspection evaluates the management of a facility and ascertains whether or not it provides for education of food-handling practices for workers to improve safe handling of foodstuffs. The inspectors also review processes in place to make certain the facility management conducts self-inspections, keep their guidelines up-to-date and create programs to prevent food contamination.

Written Policy and Procedures:

Inspectors will review the facility’s written policy statement to ensure the 3PL provider is committed to producing safe, uncontaminated food products for consumers.

Accountability:

AIB inspectors look at the organization chat of the program in place and make certain the facility has a qualified and designated supervisor in place to oversee and implement the Prerequisite and Food Safety Programs.

Training and Education:

The AIB strives to ensure the facility holds regularly scheduled training and educational sessions for all personnel, whether line workers or upper-management. They will verify that records of training are maintained and that refresher courses are given at least once a year.

Traceability Program/Recall Program:

Again, this is our presentation of two criteria that go hand-in-hand. AIB inspectors will review the written traceability program to ascertain the facility can quickly locate food products suspected of contamination. The inspectors will also review the written recall program to make certain that potentially contaminated foods can be quickly removed from the marketplace.

Hazard Analysis and Critical Control Points (HACCP) Program:

This is an in-depth review of the HACCP program in place to make certain steps have been taking in the production of food products, from manufacturing to shipping, to ensure the food products are safe from microbial, physical or chemical contamination.

Making The Grade

During an AIB inspection, an Inspector tours the facility and gives a grade based on these five standards. If the facility scores less than 70% of the total, or scores less than a 65% on any particular standard, or fail to meet certain key requirements, they will not pass the inspection. If a facility scores in the top 25%, they are awarded a “Recognition of High Achievement”.

What Does This Mean For You, the Customer?

If you are a potential 3PL customer who needs a dedicated food-handler, receiving a “Recognition of High Achievement” from the AIB should be one of the most important factors in your decision-making process. Receiving a high score from the AIB will provide you peace of mind, knowing that your 3PL partner will handle food in the proper manner.